Polycarbonate (PC) is a versatile material with a range of properties that make it an excellent choice for various industrial applications. Known for its strength, clarity, and durability, it is a preferred material for creating custom parts, especially using CNC technology. But can polycarbonate be CNC machined effectively?

This article will explore the details, key considerations, and steps to ensure successful machining of polycarbonate.

Key Points:

- Polycarbonate is highly suitable for CNC machining.

- Special precautions are necessary to avoid issues with heat.

- Tools and settings must be optimized for the material.

- Post-processing can enhance the finish of machined parts.

Properties of Polycarbonate

Polycarbonate, commonly referred to as PC, is an amorphous thermoplastic. It softens before it melts, allowing it to withstand higher temperatures than some other materials, such as acrylic. Its impact resistance, clarity, and lightweight nature make it a popular alternative to glass. It is frequently used in applications where transparency and durability are essential.

One of its primary advantages is its toughness. It can handle significant wear and tear while maintaining its integrity, making it ideal for use in safety equipment, lenses, and even bulletproof windows. It is often the material of choice for parts that need to endure high-impact environments without sacrificing visual clarity.

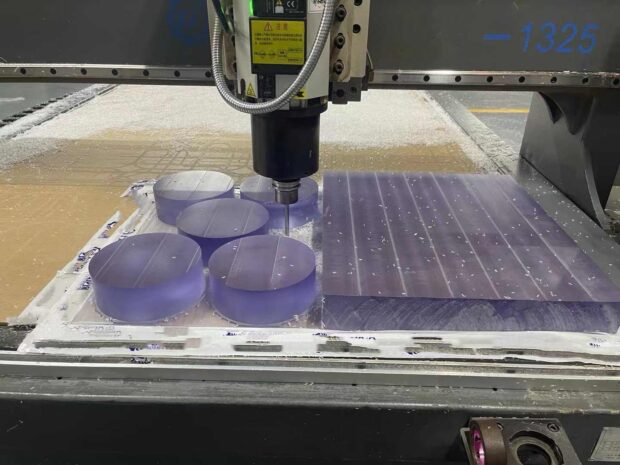

Is CNC Machining Suitable for Polycarbonate?

Yes, polycarbonate is well-suited for CNC machining. However, certain factors must be considered to ensure the process is smooth and efficient. Given the material’s heat sensitivity, care must be taken to avoid excess heat, which can cause the PC to soften or deform. Proper tool selection, speed adjustments, and cooling methods are critical to preventing heat-related issues.

For those seeking high-quality CNC polycarbonate machining services, Dongguan Runsom is a trusted provider with over a decade of experience in the industry. Runsom Precision specializes in custom CNC machining from rapid prototyping to large-scale production. They craft parts for various industries, including aerospace, medical, automotive, and electronics, using both plastics and metals. Their commitment to quality and efficiency ensures that customer needs for precision-machined parts are met under tight lead times.

Key Considerations for Machining PC

Several key points must be addressed when machining polycarbonate to ensure high-quality results:

- Tool selection ─ Carbide tools work best for machining polycarbonate. These tools help minimize heat buildup and reduce the risk of the material warping during the process.

- Cutting speed ─ PC requires careful attention to cutting speed. Slow and steady speeds are preferred, as faster cutting can generate excess heat, which may cause the material to soften or melt.

- Feed rate ─ The feed rate should be moderate. Too fast of a feed can result in rough edges or cracks, while too slow can increase the risk of heat damage. Balance is key to achieving clean, precise cuts.

- Coolant use ─ Coolant plays an essential role in managing the temperature during CNC machining. It helps dissipate the heat generated by the cutting process and prevents deformation. Ensure that coolant is applied in a steady and consistent manner throughout the machining process.

- Tool pathing ─ To avoid excessive heating, it’s important to design tool paths that reduce the number of passes over the same area. Minimizing tool retraction and limiting rapid movements can help maintain a stable temperature.

Post-Machining Finishes

After CNC machining, polycarbonate parts can be polished to restore clarity and improve surface quality. Sanding is often required to remove rough edges or imperfections, and flame polishing is a common method used to achieve a smooth, glass-like finish. However, care must be taken when applying flame polishing to avoid overheating or warping the material.

In addition, chemical polishing is sometimes used to further enhance the transparency of the machined part. Solvent-based polishing techniques can yield excellent results, especially for parts where optical clarity is a critical requirement.

Common Applications of CNC Machined Polycarbonate Parts

PCs are used in a wide range of industries. Some common applications include:

- Optical lenses ─ Its clarity and toughness make it an ideal material for lenses in both industrial and consumer products. CNC machining allows for precise shaping and customization.

- Protective equipment ─ Helmets, shields, and other safety gear are often made from polycarbonate. Its impact resistance ensures long-lasting protection in harsh conditions.

- Electronic housings ─ PC is often used in electronics for creating durable, lightweight housing that protects sensitive components from damage.

- Medical devices ─ Due to its biocompatibility and durability, polycarbonate is widely used in medical equipment, including surgical instruments and diagnostic tools.

Challenges of CNC Machining Polycarbonate

While polycarbonate is a robust and adaptable material, certain challenges may arise during CNC machining:

- Heat sensitivity ─ PC softens at higher temperatures. Excess heat can cause deformities or melting. Preventing heat buildup is critical to maintaining part integrity.

- Brittleness in thin sections ─ When machining thin sections of polycarbonate, the material may become more brittle, increasing the likelihood of cracks or breaks. Extra care is needed during toolpath planning to minimize stress on thinner areas.

- Tool wear ─ Machining polycarbonate can cause significant tool wear, particularly if improper tools or speeds are used. Carbide tools help mitigate this issue, but regular monitoring of tool conditions is essential.

Tips for Successful CNC Machining of Polycarbonate

- Test settings first ─ Before running a full production cycle, always test your CNC machine with small polycarbonate samples to ensure optimal settings are used.

- Use sharp tools ─ Dull tools can generate excessive heat and cause poor surface finishes. Keep your cutting tools sharp for the best results.

- Monitor temperature ─ Pay close attention to the temperature of both the tool and the PC part throughout the process to avoid heat-related issues.

- Avoid excessive re-cuts ─ Minimize the need for re-cutting or going over the same area repeatedly, as this increases the chances of heat buildup.

FAQ

Is coolant necessary during CNC machining of polycarbonate?

Yes, using coolant helps to prevent heat buildup and ensures the polycarbonate does not soften or deform during the process.

What types of tools should be used for machining polycarbonate?

Carbide tools are recommended due to their durability and ability to handle the material’s properties without excessive wear or heat.

What post-processing options are available for polycarbonate parts?

Polishing, sanding, and chemical treatments can be used to enhance the surface quality of machined polycarbonate parts.

Can polycarbonate be machined into very thin sections?

While possible, thin sections can become brittle, so additional care is required during machining to avoid cracks or breaks.

Conclusion

CNC machining polycarbonate requires attention to detail but offers significant advantages. It allows for the creation of custom parts with high precision and durability. By carefully controlling heat, using proper tools, and applying finishing techniques, high-quality PC parts can be produced efficiently.

Jewel Beat

Jewel Beat